Main features

- Adopt France/SCHNEIDER touch screen human-computer interface, operate and control easily.

2.Adopt Germany REXROTH PC control, Integrated with optical fiber, ensure high speed running steadily.

- Germany REXROTH servo motor and German SICK Photoelectric eye correction, tracking printing bag accurately.

4.Raw material load adopt pneumatic cylinder up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt YOUDAO, reduce adjustment time.

The main features of flexo printing

1.The ink is transported by a separate gear motor, and the ink pump circulates the ink.

2.Use a closed scraper to scrape ink, ensure high-speed printing and prevent ink splash.

3.Pneumatic lift and drop mode, automatically start after shutdown, automatically transport ink after printing plate installation,Printing plate automatic printing after booting.

4.Independent closed type hot and cold dual function drying system.

|

Model |

G350J |

|

Cut bag length(C) |

165—715mm |

|

Print the length of the cut bag |

160—710mm |

|

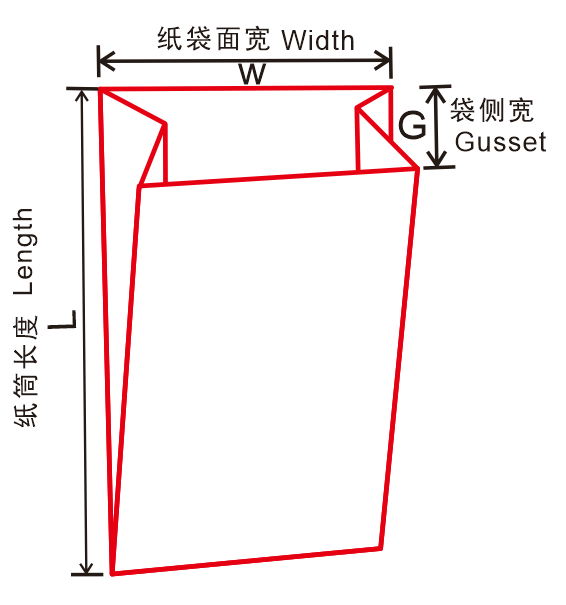

Paper bag width(W) |

70—350mm |

|

Insert size |

20—120mm |

|

Bag mouth height |

15/20mm |

|

Planar graph |

|

|

Paper thickness |

35—80g/m² |

|

Machine Speed |

50—700pcs/min 140m/min |

|

Paper bag speed |

50—650pcs/min |

|

Paper roll width |

160—960mm |

|

Roll paper diameter |

Φ1000mm |

|

Inner diameter of paper |

Φ76mm |

|

Printing Area |

|

|

Print paper roll width |

160—960mm |

|

Printing length |

160—710mm |

|

Printing speed |

0—140m/min |

|

Color accuracy |

≤±0.20mm |

|

Plate thickness (Including the thickness of the double-sided tape) |

2.28mm 0.38mm |

|

Working Air Current |

≥0.36m³/分钟,0.5—0.8MPa More than 0.36m³/ minutes, 0.5—0.8 MPa |

|

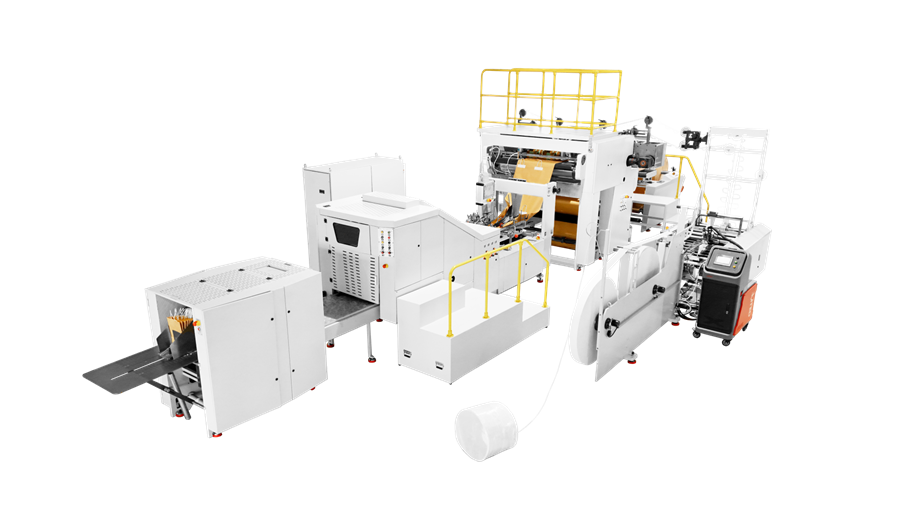

(With printing press)Machine power |

380V 3(phase) 4(wire) 40.3KW |

|

(With printing press)Total weight |

10000kg |

|

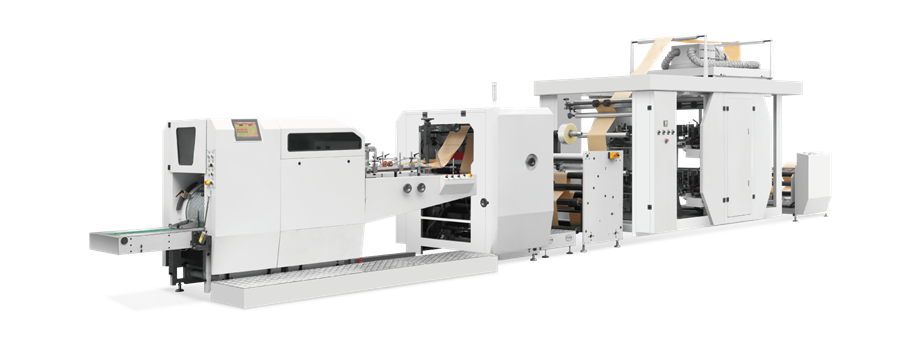

(With printing press)Machine Dimension |

12000x2200x2800mm |

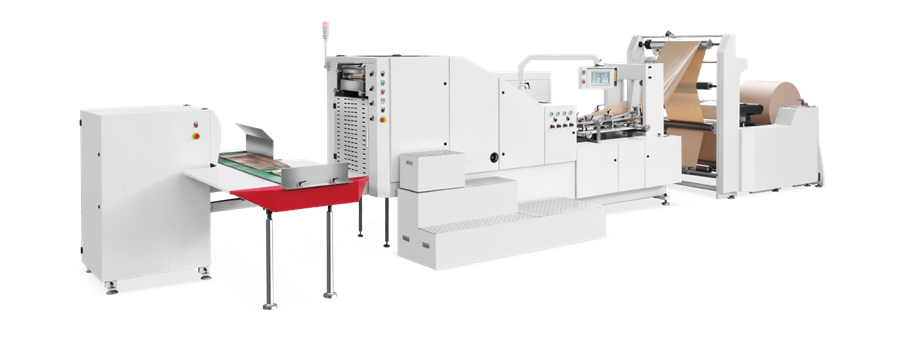

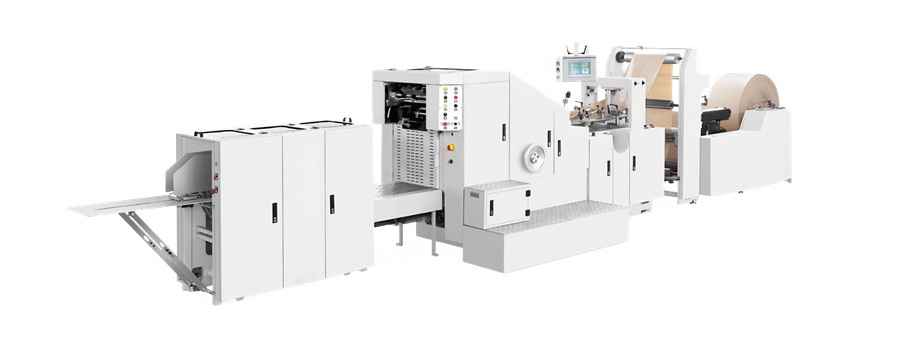

G350J-Fully Automatic High Speed Flat Bottom Paper Bag Machine Could Be Customized Without 2 Colors Printing Machine.

Please send inquiry to get more detailed information.

Reference Picture as below: