Main features

- Adopt France/SCHNEIDER touch screen human-computer interface, operate and control easily.

2.Adopt Germany REXROTH PC control, Integrated with optical fiber, ensure high speed running steadily.

- Germany REXROTH servo motor and German SICK Photoelectric eye correction, tracking printing bag accurately.

4.Raw material load adopt pneumatic cylinder up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt YOUDAO, reduce adjustment time.

|

Model |

450AT |

|

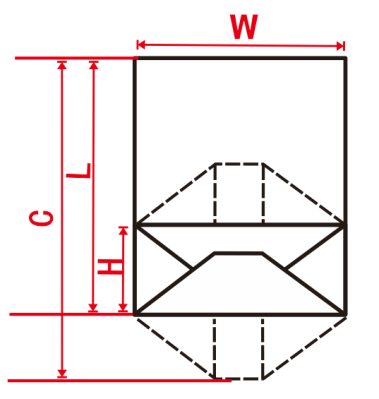

Cut bag length(C) |

300—630mm |

|

Cut the length of the handle paper bag |

300—530mm |

|

Paper bag width(W) |

220—450mm |

|

The width of the handle paper bag |

240—450mm |

|

Paper bag bottom width(H) |

100-200mm |

|

Planar graph |

|

|

Paper thickness |

80—150g/㎡ |

|

Machine Speed |

30—150pcs/min |

|

Paper bag speed |

30—120pcs/min |

|

Paper roll width |

670—1330mm |

|

Roll paper diameter |

Φ1500mm |

|

Inner diameter of paper |

Φ76mm |

|

The handy paper bag weighs heavily |

80—150g/㎡ |

|

The paper roll width of the handle |

710—1330mm |

|

Round Rope Machine Requirements |

|

|

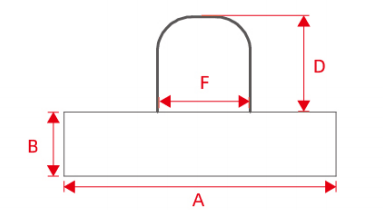

Handle length |

380mm |

|

Patch length(A) |

190mm |

|

Hand patch width(B) |

45—50mm |

|

Handle distance(F) |

95mm |

|

Paper rope height(D) |

100mm |

|

Rope diameter |

Ф3—5mm |

|

patch paper roll diameter |

ф1200mm |

|

patch paper thickness |

90—110g/㎡ |

|

Round rope drawing |

|

|

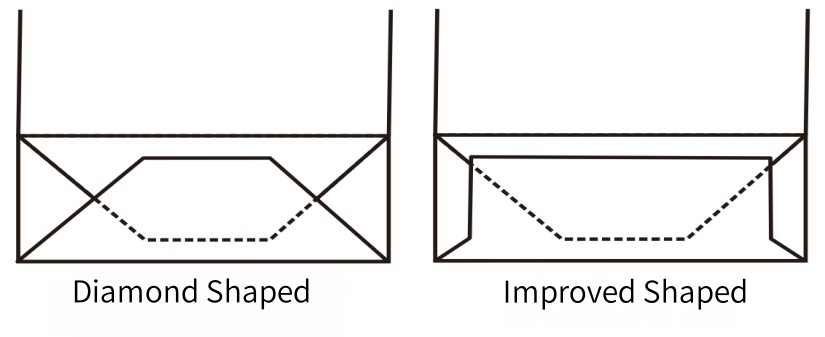

Bottom folding type |

|

|

Cutting knife |

Sawtooth cutting |

|

Machine power |

380V 3(phase) 4(wire) 42KW |

|

Total weight |

15000kg |

|

Machine Dimension |

15300x5500x3200mm |

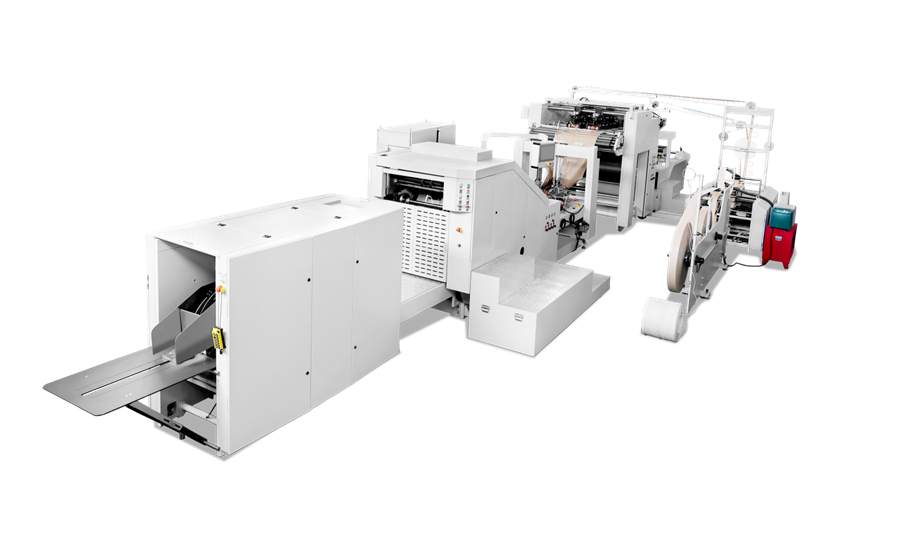

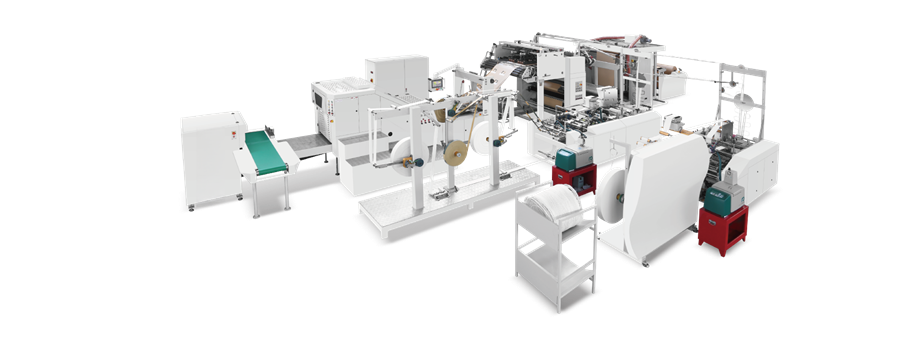

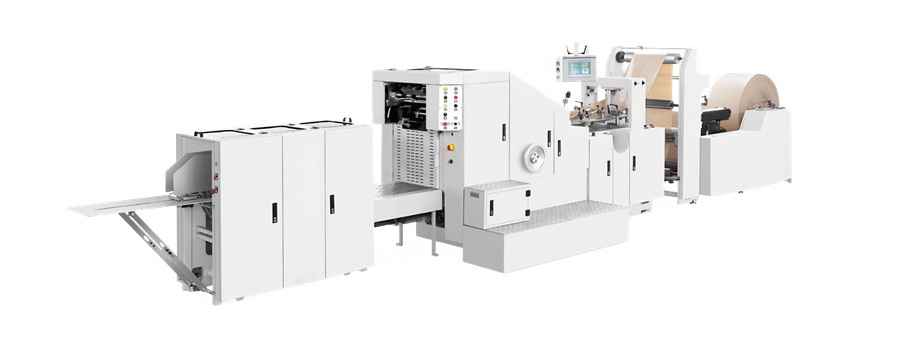

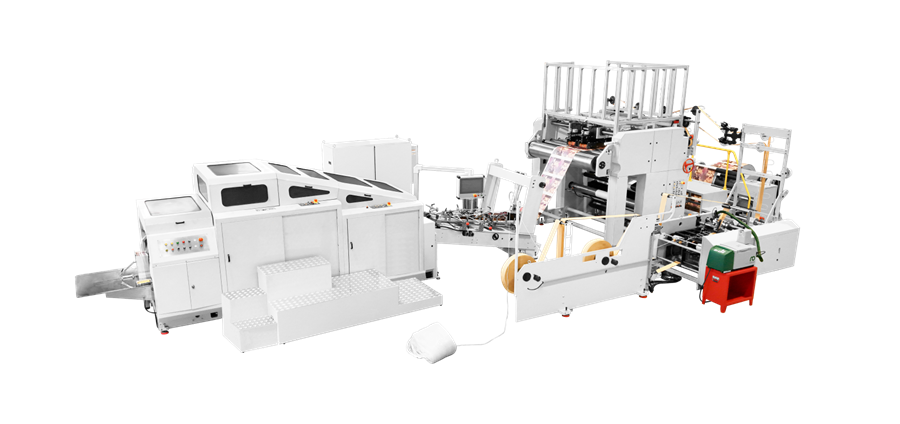

450AT-Automatic High Speed Square Bottom Paper Bag Machine Could Be Customized With 2 Colors Printing Machine.

Please send inquiry to get more detailed information.

Reference Picture as below: